Easy processing - like wood

Salamander outdoor profiles do not differ from wood in look and feel, nor in processing. Thus, they can be sawn, milled, drilled, glued, sanded, glazed, painted and bent like wood.

Best of all, unlike wood, Salamander outdoor profiles do not crack, swell or splinter.

NOTE: In the case of glazing/painting, the respective color tone of the profile is naturally highly dependent on the base material, sanding pattern and paint application quantity. Therefore, no liability can be accepted for color variations or differences between the profiles supplied.

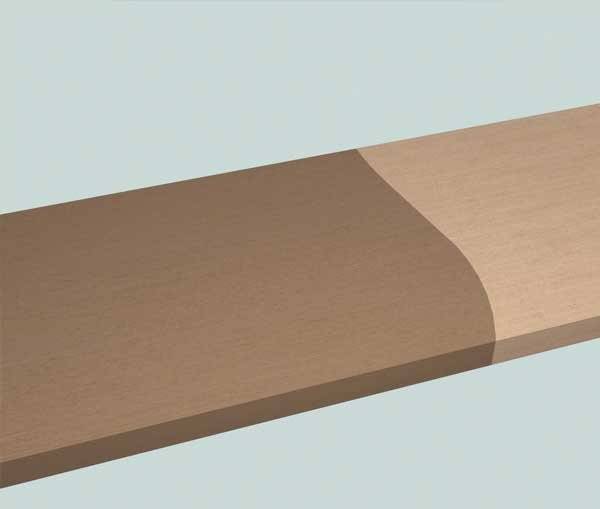

In order to achieve a uniform appearance of the installed profiles, it is recommended, especially in the facade area, to process profiles from several packages at the same time, i.e. to cross-mix them from at least five to six packages/pallets. Only in this way are the profiles optimally mixed and the natural play of colors is shown in its uniform beauty.

As your reliable system partner, we want to give you access to the most important documents you need for your project planning around the clock and independently of our office hours. For this reason, a comprehensive portfolio of technical data as well as information and marketing material is available for download in our service area.

/// SAWS

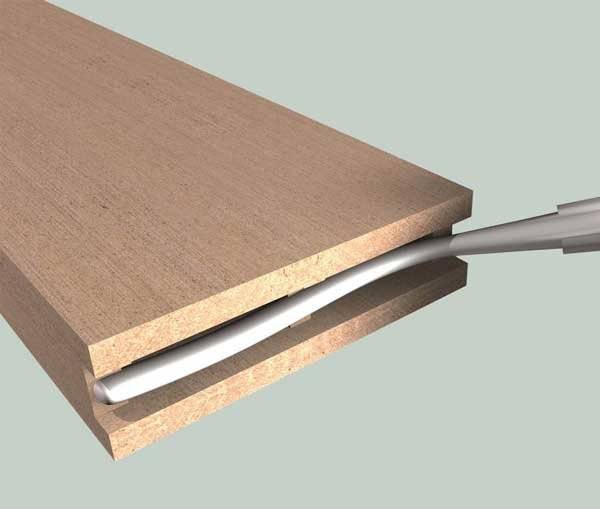

/// FREAS

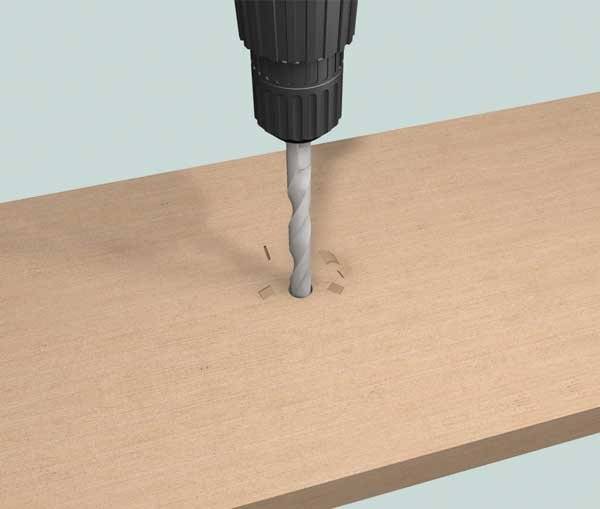

/// DRILLING

/// ADHESIVE

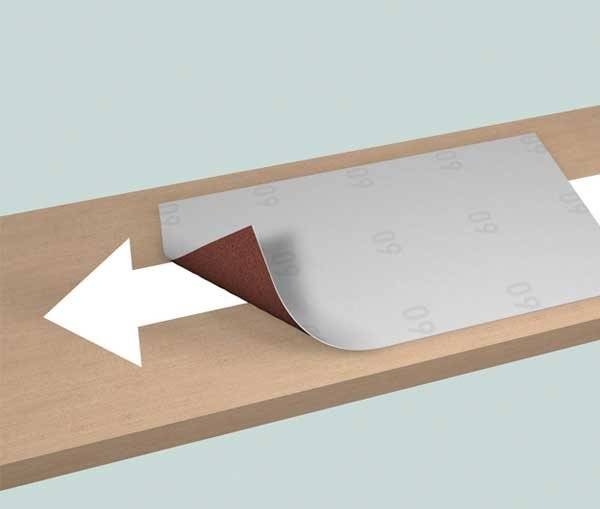

/// GRINDING

/// GRINDING

/// BOW

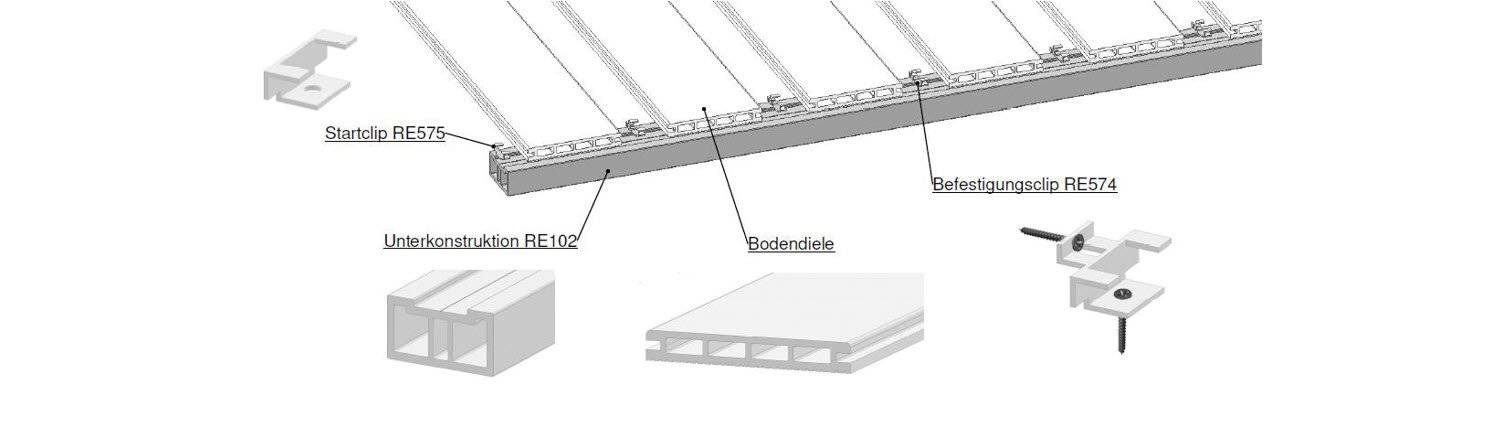

In order to install Salamander brand Resysta decking in your garden, you should consider the following points in advance:

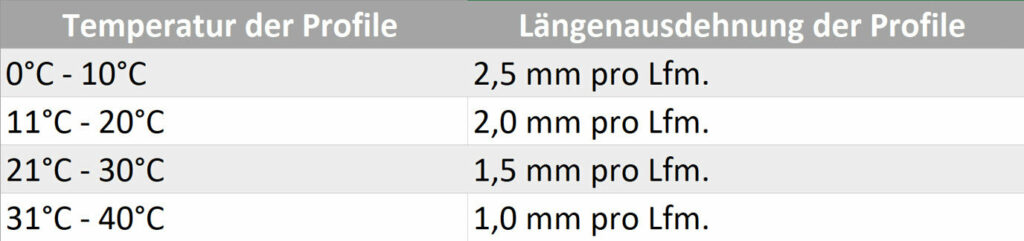

Example: At a material temperature of 15°C and a profile length of 3000 mm, a distance of 6 mm is required during installation.

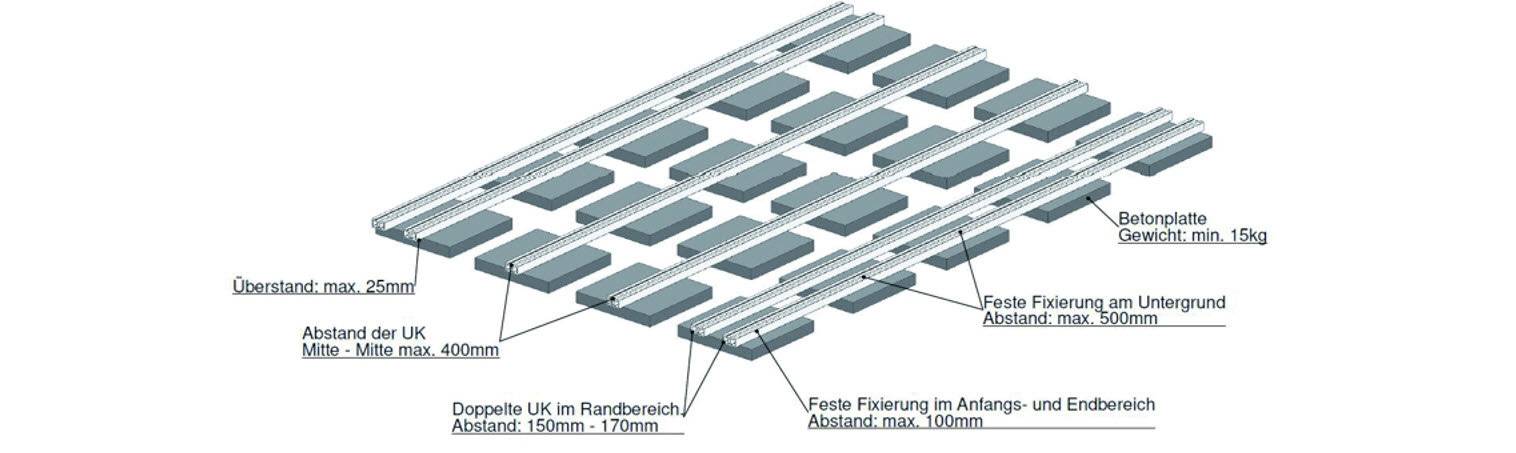

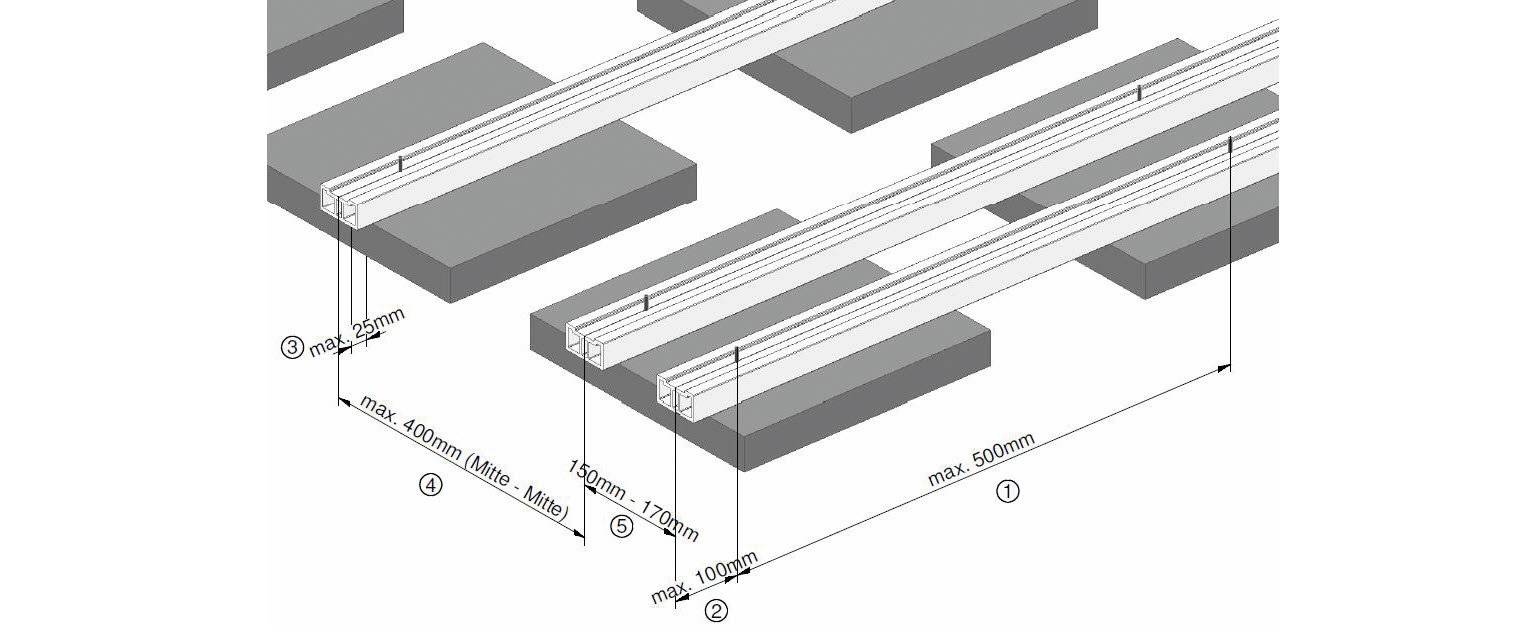

Fix the substructure profiles firmly to the substrate at a maximum distance of 500 mm. A strip foundation or concrete slabs are suitable here, for example.

Screw the start clip to the substructure. If the distance between the screw and the start of the substructure is less than 15 mm, pre-drill with a diameter of 2 mm.

ttp plastic profiles

From the idea to the development to the finished profile. Since 1958, ttp Papenburg GmbH has been manufacturing individual profiles from a wide variety of plastics at the Papenburg site in northern Germany to customer specifications.

Products

Contact

Schulze-Delitzsch-Strasse 23-25

26871 Papenburg

Feel free to contact us by phone, by mail or via our contact form.